The AGRI-TRAC texture is significantly different from Grooving, Scabbling or Rubber flooring. Heat detection increases, resulting in more milk production, and involuntary cull rate is reduced because of fewer injuries from falls and foot and leg disorders. AGRI-TRAC reduces and almost eliminates the “slip & catch” concept of all other available choices that results in de-lamination, inter-digital injury and bacterial exposure (digital dermatitis & sole ulcer infections) because of volumes of manure left behind in deep wide grooves after cleaning.

Our “TRACTION MILLING” process works on all patterns of concrete including; slats, diamond grooved, imprinted and broom finished flooring. The equipment is compact and versatile and allows access to tight areas like return alleys and cross-overs in addition to the traditional open spaces such as holding areas, alleys and parlour areas. Watch the video below to get a glimpse of the AGRI-TRAC 7-step patented procedure.

The surface of a poured concrete floor is only sand and Portland cement. The part that gives concrete its strength is in the larger aggregate (stones) under the surface. If the concrete is of reasonable strength with quality ingredients it will not be affected at all. Unless your original floor surface was polished smooth and sealed with epoxy, it was already porous. If there were no concerns about acids and frost before, there won’t be afterwards.

As mentioned above, the aggregate is the hardest part of concrete. The AGRI-TRAC texture is ground into these stones. The stronger the concrete mix, the longer it will last. Also, by using a rubber scraper instead of steel, the texture will last considerably longer, especially if it scraped several times a day. Since AGRI-TRAC is lowering the level of the floor surface slightly, we leave narrow strips of the original surface for scrapers and buckets to ride on to protect the lower texture. Alley scrapers have very little down pressure compared to bucket type scraping so do not wear down a floor very much, unless sand bedding is being used. At that point, everything wears out quicker.

On a new barn floor, you want a flat textured surface so as to hold as little manure as possible after scraping. A broom finish on a freshly poured floor will get you about 6 months to a year of good traction. Rollerbug texture will last 2-5 years. If you want us to do your new barn, we can and then you don’t have to worry about traction for 6-15 years depending on whether you have sand-bedding or traditional straw, sawdust or compost bedding. Either way, you have significantly less manure left behind on the floors compared to grooving.

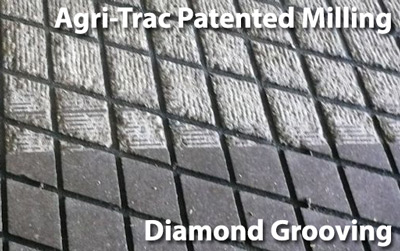

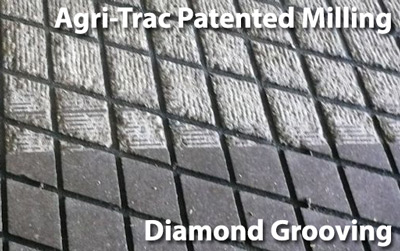

Seventy percent (70%) of the floors we have done are over top of grooving. The customer consensus is that a smooth floor is 0% traction and pasture is 100% traction. Grooving, scarifying, scabbling & rubber will offer about 30% improvement. AGRI-TRAC offers 80% traction. You cannot expect to duplicate pasture on concrete, but we get more than double of other alternatives. Get the prices of those options and call 1-877-966-3546 to get a quote on your project and decide from there. We are more than competitive once these facts have been considered.

We are a Canadian company as well as having a United States Corporation. We can go anywhere in Canada and the U.S. Our price structure per square foot for each independent country does not change from region to region, but we do need to have enough square feet to do to initially go to that region. This is why we make a special offer to anyone who calls from an area that does not have enough area to cover the travel expenses. The offer entails that advertising material will be provided for that individual to pass onto neighbours & friends that may need our services. For every job in that area that was done through the initial customers efforts, he will receive a discount on his invoice. We have had customers that have almost paid for their own job by referrals. It pays to be the first to call in your area!

Yes. All equipment is thoroughly washed after each job or farm location. Clean clothes are also worn to each job. If there is any extra protocol and disinfectants (such as Verkon) already in place on the farm, we are happy to do that as well. AGRI-TRAC is very serious about the protection of the livestock industry from transmittable diseases.

All other methods of trying to reduce slippage leave a large portion of the existing floor surface untouched and still slippery. AGRI-TRAC eliminates the entire top one eighth of an inch of existing surface and leaves a fine ribbed pattern in the concrete about a quarter inch apart.

ROLLERBUG is a full surface finish that can be put into the concrete at the time the concrete is being poured. Some people think the only solution to prevent lameness is to pour smooth concrete and then groove the concrete. Unlike grooving which works on a slip and catch principal, ROLLERBUG provides a slip free surface for 2-5 years which aids in preventing impact damage to the hoof. Doing this process to freshly-poured concrete eliminates future inter-digital strains and corns which are associated with slip and catch grooving. For more information, check out the video below or contact us today.

We are the only ones in North America that provides this service with our highly trained crews and patented equipment (we have both U.S. and Canada patents). We would be interested in being contacted by anyone interested in providing this service in their area as a joint-venture partnership like we already have in several locations.